For the first time in Mongolia, a public–private partnership has enabled the reuse of treated industrial wastewater from MCS Coca-Cola LLC for the technological operations of Amgalan Thermal Power Plant. As a result, Amgalan Thermal Power Plant has become the first state-owned power plant in the country to implement a green solution, marking a historic milestone in advancing Ulaanbaatar’s energy and water management sectors. At the request of the Ministry of Environment and Climate Change, the World Bank’s 2030 Water Resources Group implemented a project between 2020 and 2024 with funding from the Korea Green Growth Trust Fund (KGGTF). The project confirmed the technical feasibility of using treated industrial wastewater from MCS Coca-Cola for the operational needs of the thermal power plant.

The two facilities are located 2.5 kilometers apart. To enable water delivery, MCS Coca-Cola invested MNT 3.5 billion of its own funds to install pipelines and additional equipment, which have been fully transferred to Amgalan Thermal Power Plant.

Amgalan Thermal Power Plant is the sole heat supply source for the eastern districts of Ulaanbaatar. From September 15 to May 15 each year, the plant will source 40 percent of its technological water needs from MCS Coca-Cola. This amounts to approximately 120,000 cubic meters of water annually, conserving groundwater resources equivalent to the average daily water consumption of 600,000 people.

Photo caption: Pipelines and additional equipment installed with an investment of MNT 3.5 billion.

While Amgalan Thermal Power Plant had already been reusing its own technological wastewater within its production processes, the addition of externally sourced treated wastewater from MCS Coca-Cola enables the plant to become a model facility with zero technological wastewater discharge.

MCS Coca-Cola LLC, recognized as a national “Water Steward” organization, has pursued environmentally responsible production policies for many years. As a pioneer in the food and beverage sector, the company commissioned its industrial wastewater treatment facility in 2010. Since then, it has treated 99 percent of all water used in production through membrane bioreactor technology and supplies the treated water free of charge to organizations for non-potable purposes.

A Historic Green Solution Introduced in the Water Management Sector

By reusing treated industrial wastewater to supply heat to the eastern districts of Ulaanbaatar, this initiative contributes to the development of a circular economy and green growth, delivering positive environmental, public health, and sustainable development outcomes, the partners emphasized.

Sh. Batbayar, State Secretary, Ministry of Environment and Climate Change:

“The Government is placing special emphasis on increasing the use of surface water and promoting water reuse. At a time when groundwater reserves are declining, we express our appreciation to these two organizations for demonstrating how the private sector can invest its own resources and work in partnership with the state. By conserving and reusing 500 cubic meters of groundwater per day, Amgalan Thermal Power Plant is making a highly commendable contribution to natural resource protection. We encourage the expansion of this technology across multiple sectors and invite other private enterprises to follow this example.”

B. Eren-Ulzii, State Secretary, Ministry of Energy:

“Today, through cooperation between the public and private sectors and international financial institutions, we are creating conditions to reuse wastewater for the technological needs of Amgalan Thermal Power Plant, thereby conserving groundwater resources. The Ministry of Energy supports the adoption of energy-efficient, effective, and environmentally friendly technologies. Located in the eastern part of Ulaanbaatar, Amgalan Thermal Power Plant supplies 13 percent of the city’s centralized heat demand. Ensuring reliable and uninterrupted heat supply in the world’s coldest capital city is a top policy priority—one that safeguards not only economic growth but also the lives and health of citizens.”

Z. Batbayar, Head of the Water Department:

“For the first time in history since Ulaanbaatar became a settled city, wastewater has been brought into circulation, opening a new chapter in our lives. Personally, I feel as joyful as a father holding his newborn child. By using treated wastewater from MCS Coca-Cola for the plant’s operations, households can enjoy greater comfort, and the sustainability of the city’s water supply is tangibly improving. This initiative goes beyond cooperation between two organizations—it safeguards drinking water security for thousands of children in future generations. I extend my heartfelt thanks to everyone involved in making this project a success.”

M. Munkhuu, Chief Executive Officer, Amgalan Thermal Power Plant:

“We are pleased to inaugurate a project that conserves precious freshwater resources, reduces environmental pollution, and advances the goals of a zero-waste economy and green development. The feasibility study was funded by the Republic of Korea’s Green Growth Trust Fund, while the MNT 3.5 billion investment for construction and equipment was fully financed by MCS Coca-Cola as part of its corporate social responsibility—without any burden on the state budget.”

L. Myagmarjav, Chief Executive Officer, MCS Coca-Cola LLC:

“I served on the council of the World Bank’s 2030 Water Resources Group for nine years. At a time when water security is critical for the eastern districts of Ulaanbaatar, we have established a strong example of public–private partnership, with the private sector taking the lead and the state providing support. Through this collaboration, we are implementing a circular, zero-waste economy and the 3R principles—reducing water use, treating used water, and reusing treated water—in practice.”

Dr. D. Dorjsuren, Chair of the Board, Freshwater Institute:

“This project is a vital initiative for strengthening Mongolia’s water security and governance. Through science-based research, optimal solutions, and multi-stakeholder partnership, a green solution has been successfully implemented via public–private cooperation. I am confident that this experience of reusing wastewater in the energy sector will be replicated nationwide. My sincere gratitude goes to all who turned this vision into concrete action to protect the environment and preserve valuable resources for future generations.”

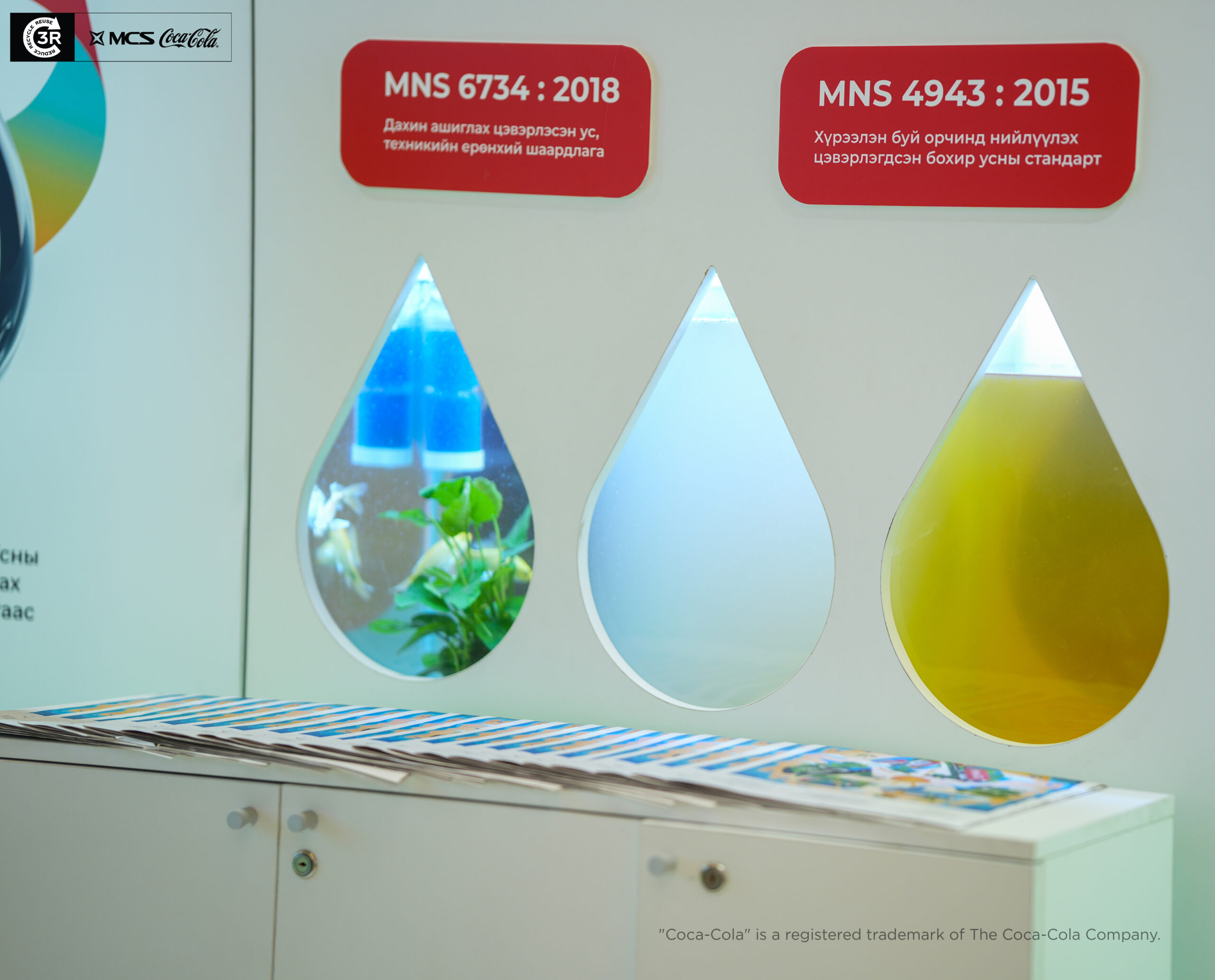

Photo caption: Fish can survive in industrial wastewater treated to a 99% purification level.

For reference, MCS Coca-Cola treats its industrial wastewater in compliance with:

• MNS 4943:2015 – Water quality requirements for discharge into the environment

• MNS 6734:2018 – General technical requirements for treated water intended for reuse

The treated water meets standards suitable for sustaining aquatic life and is used for road cleaning, landscaping, and irrigation of green spaces and parks. To further expand the use of treated industrial wastewater and protect groundwater resources, organizations can obtain water from MCS Coca-Cola between May 15 and September 15 each year.

Trophy Winner: Metagro LLC

2nd Place: Energy Resources LLC

3rd Place: Top Motors LLC

Trophy Winner: Metagro LLC

2nd Place: Energy Resources LLC

3rd Place: Top Motors LLC

Trophies and certificates made from recycled plastic

Trophies and certificates made from recycled plastic